Seamless Turnkey Design-to-Manufacture Integration Services

Most design firms don’t manufacture. Most manufacturers don’t help you design.

Trustbridge does both.

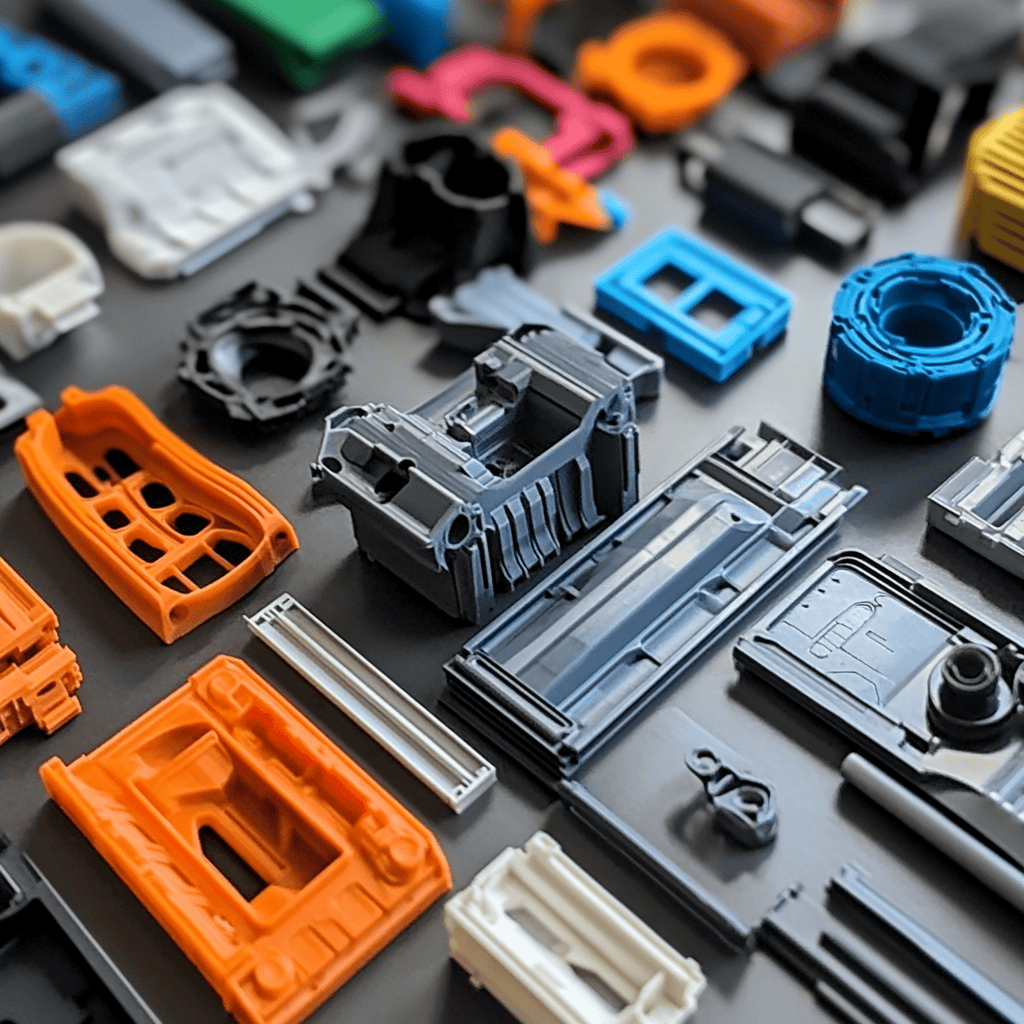

Our Turnkey Design-to-Manufacture Integration service eliminates the disconnect between concept and production by providing a single, coordinated team from ideation through delivery. We design parts that are ready to be made and then we make them through our global network of certified manufacturing partners. No handoffs. No miscommunication. No wasted time or tooling dollars. Just a clean, scalable path from idea to finished product — with complete technical oversight and clear accountability.

Our Turnkey Design-to-Manufacture Integration Services at a Glance

Explore Related Services

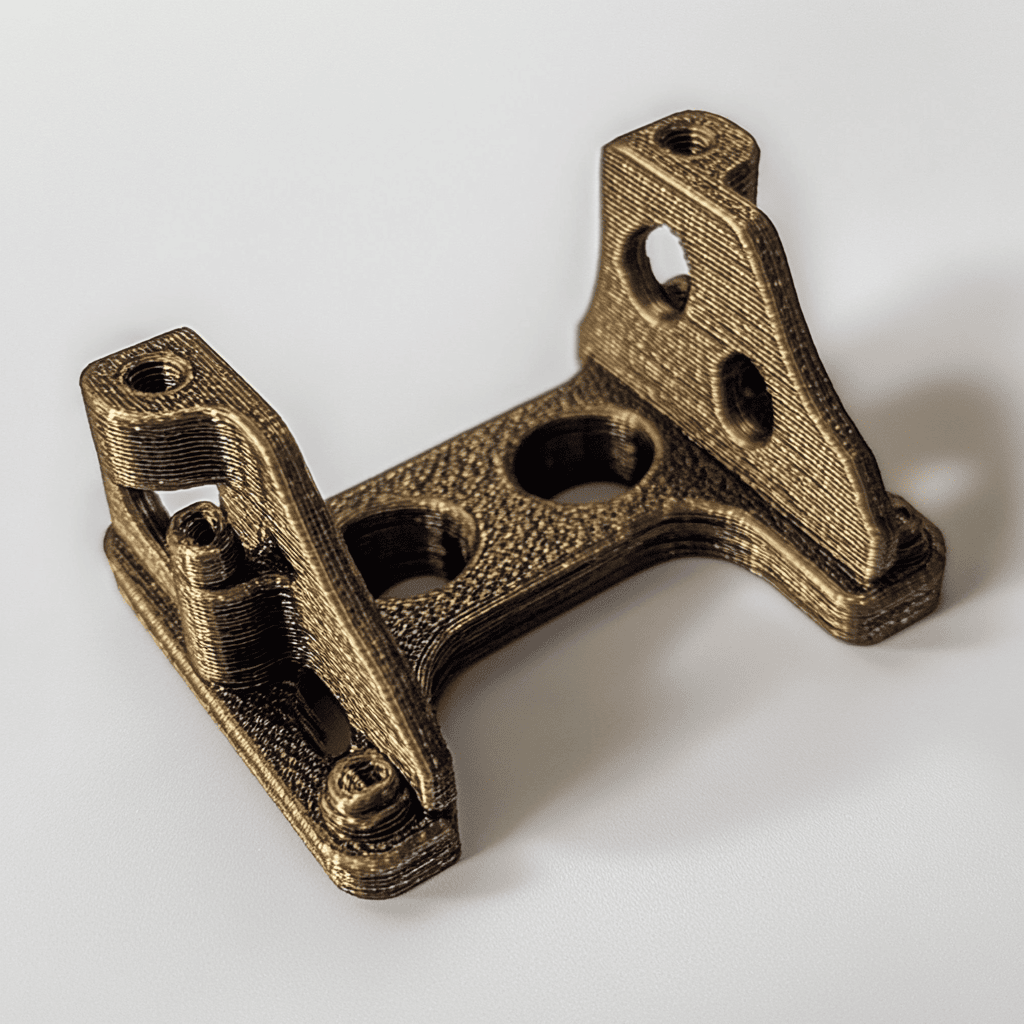

3D Printing

Rapid, cost-effective prototyping and low-volume production with complex geometries and minimal tooling.

Sheet Metal Fabrication

Cut, bend, and assemble custom enclosures, brackets, and panels — scalable from prototypes to full production runs.

Injection Molding

High-volume plastic part production with consistent quality, fast cycle times, and low per-unit cost once tooled.